Table of contents

What is fertigation and what is it based on?

The need to optimize the resources destined to the correct development of the crop, considered as production factors, determines the use of different techniques to obtain the maximum economic yield.

Fertigation is the simultaneous application of water and nutrient solutions to the crop, using driplines and emitters as drippers. This method allows a precise and controlled application of nutrients directly to the active root zone of the plants.

Systems used for fertigation

The systems used vary from simple manual injection systems to sophisticated automated systems with multiple injectors and electronic controllers that allow regulating the frequency and quantity of inputs in a precise way according to the specific needs of the crop and soil conditions.

Types of fertilizers in fertigation

Fertilizers used in fertigation are water soluble and can be of mineral or organic origin. The most common include nitrates, phosphates, potashes and micronutrients. These fertilizers are selected according to crop needs and specific soil conditions.

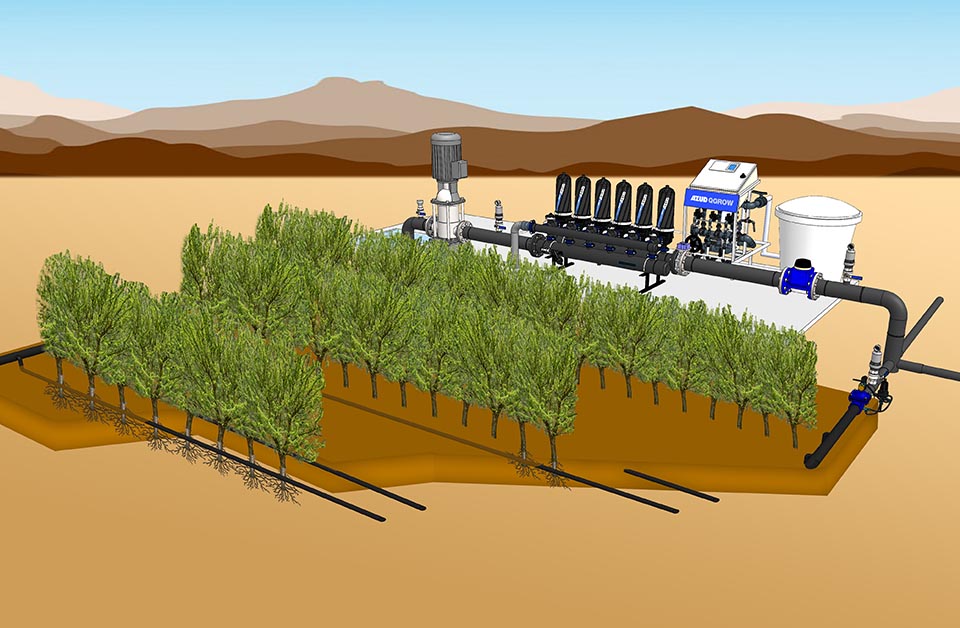

Irrigation systems suitable for fertigation

The most suitable irrigation systems for fertigation include drip irrigation, sub-surface drip irrigation and micro-sprinkler irrigation. These systems allow for uniform distribution of water and nutrients, minimizing evaporation and runoff losses. Drip irrigation is especially effective in fertigation because of its ability to maintain a constant and localized supply of nutrients.

Benefits of implementing fertigation

The undeniable economic and agronomic advantages of fertigation are due to the inherent characteristics of the fertigation process itself:

- Joint application of irrigation water and fertilizers required by the crop.

- Location of these requirements only next to the active root system.

- High application frequency.

- Ease of fertilizer application and labor savings. The application of fertilizers through the fertigation process is not conditioned by the availability of personnel or inclement weather and represents a lower operational cost compared to the cost of applying fertilizers directly to the soil by hand or mechanically.

- Efficient use of the fertilizers provided. The application of nutrients in a localized manner in the active root area and highly fractionated throughout the crop cycle guarantees an adequate availability according to the needs of the plant at each moment, which allows a better use of the nutrients provided, reducing the percentage of losses caused by leaching, especially of nitrogen. As fractionation increases, losses due to leaching and/or blockage of nutrients in the soil decrease.

- High availability of nutrients. The localized application together with the high frequency and fractioning of the inputs demanded by the crop favors their availability and the ideal conditions for the assimilation of the water and nutrients supplied.

- High control in the dosage and fractionation of the fertilizers supplied. The supply of water and nutrients to the crop, in a highly controlled manner, allows adjusting the application doses to the real needs of the crop, depending on the phenological stage of the crop and the desired productive objective. With this practice it is possible to increase crop yields, obtaining the desired balance between increased production, improved crop quality and earliness or date of entry into production.

Multi-injection fertigation equipment

Of all the existing systems for the supply of the nutrient solution required by the crop, the systems based on the use of Venturi injectors are the ones that offer the most advantages, whether economic and/or agronomic.

Characteristics of a multi-injection equipment

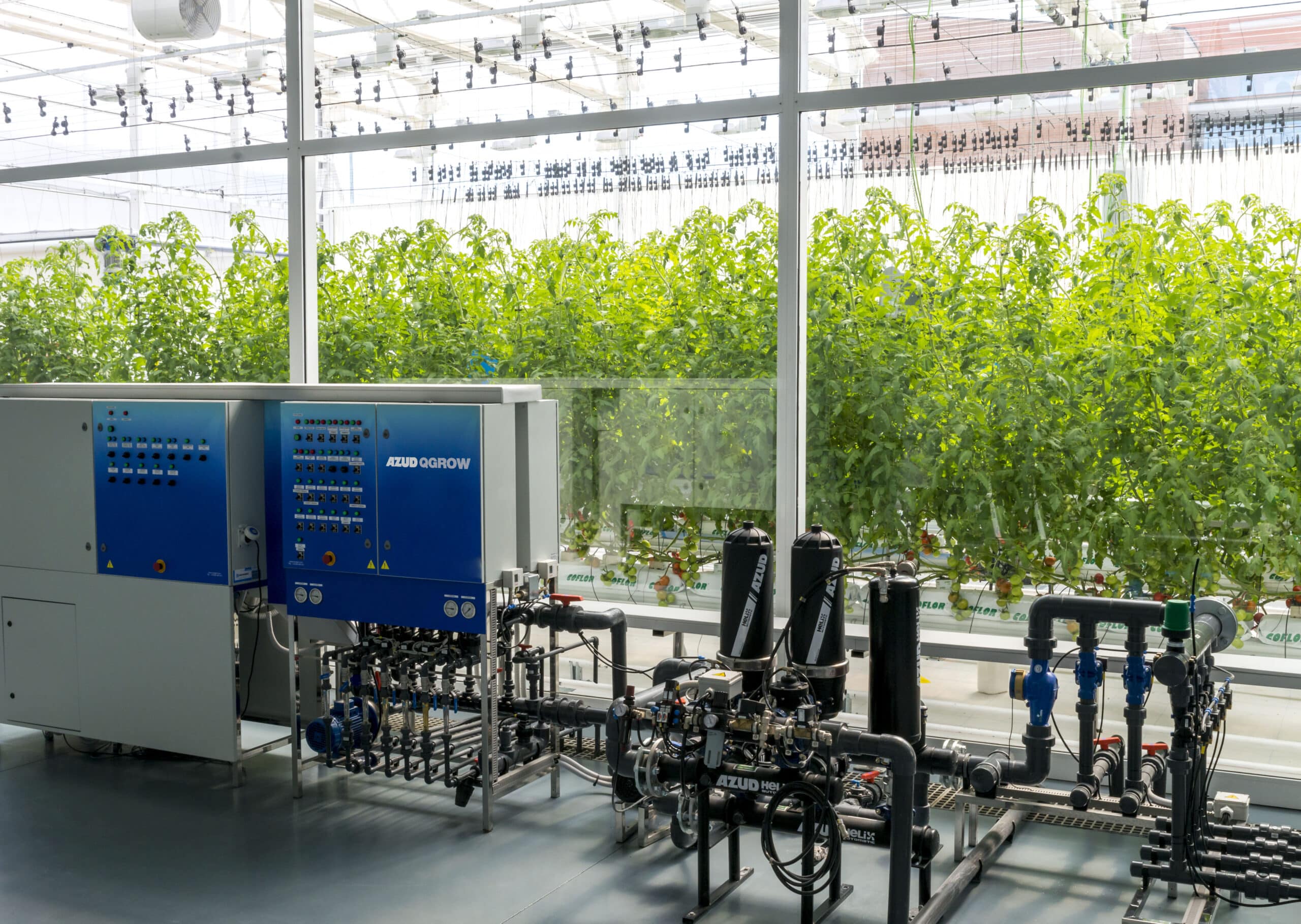

AZUD QGROW multi-injection systems perform a proportional and balanced nutrition through the controlled and simultaneous incorporation of all fertilizers with the frequency, quantity and nutritive balance required to achieve the desired productive objective.

The multi-injection system is composed of a set of manifolds (supply and return) that allow the parallel interconnection of the probe holder kit and the injection arms that make up the equipment.

- The probe holder kit incorporates the housing for connection of the pH and EC probes together with the interconnection elements to the feed and return manifolds.

- Each multi-injection arm groups the set of elements that allow injection (Venturi injector), visualization and control of injection conditions (flow meter and solenoid valve) as well as protection and control elements (filter, check valve, control valve).

Benefits of multi-injection in fertigation

- Balanced nutrition: It is possible to adjust, in quantity and proportionality, the unit injection level of each of the fertilizers to be injected simultaneously to achieve the nutrient concentration and nutrient balance required to reach the desired productive objective.

- The nutrition of the crop by means of a multi-injection system does not require the preparation of the mother solution, it allows the simultaneous application of incompatible fertilizers and at the same time allows a more versatile and dynamic nutrition by being able to adjust independently the nutritive balance required by each of the irrigation sectors.

The ease and possibilities offered by these equipments for the automation of the fertigation process conditions the use of elements that provide autonomy, versatility and control of this process. The complete automation of crop fertigation leads to substantial improvements: higher productivity of water and nutrients supplied and a productive level with an adequate balance between earliness, quality and quantity of the plant organ with commercial value.

Advantages of automating multi-injection systems

Automation allows the fertigation process to be carried out in a comfortable and efficient way, providing the following economic and functional advantages:

- System autonomy: The automation of the water and nutrient supply process allows the irrigation practice to be carried out completely autonomously without the direct intervention of the operating personnel, avoiding the dependence and availability of the operating personnel to carry out the supply with the required frequency and duration.

- Efficient nutrition: The automation of the fertigation process allows a highly fractioned input and a precise control of the desired unit quantity and nutritional balance guaranteeing optimal injection levels thus achieving a higher profitability of the fertilizers provided: lower percolation losses, higher absorption rates due to the high humidity existing in the active root zone and the possibility of adapting the pH level to the optimal values that guarantee a higher absorption.

- Versatility: The possibility and facility to establish in each irrigation sector the injection rates and the proportionality between the different fertilizers that are injected simultaneously makes AZUD QGROW multi-injection systems highly flexible tools. It allows the supply of nutrients based on application time, proportional supply to the flow rate or by controlling the pH and EC values.

- Traceability: It allows to know the injection levels. Instantaneous injection flow rates and accumulated volumes of each of the fertilizers incorporated to the crop. The information storage capacity, highly useful for the user, gives a wide knowledge of the nutrient input levels and the period in which they have been made.

How to implement a multi-injection fertigation system?

- The implementation of this equipment to the irrigation system is done by means of a bypass connection.

- The by-pass flow enters the multi-injection system through the inlet manifold which, fed by one of its ends, allows the motor flow to be distributed jointly to all the Venturi injectors integrated in the equipment and to the probe holder kit. The pressure value in the manifold corresponds to that available in the irrigation system.

- The return manifold allows to jointly collect the motive flow together with the flow of nutritive solution water aspirated by all the Venturi injectors integrated in the unit together with the transit flow derived through the probe holder kit. The total flow is conducted to the suction line of the auxiliary electric pump.

- The auxiliary electric pump provides the pressure value necessary to incorporate the flow coming from the return manifold to the irrigation line.

AZUD plant nutrition solutions

Manual fertigation equipment

AZUD has two ranges of fertigation equipment with manual regulation for simultaneous multi-injection of nutrients to the irrigation system: AZUD QGROW BS and AZUD QGROW V.

AZUD manual fertigation equipment offers a series of features that improve productivity and efficiency in the application of nutrients. They stand out for their capacity of homogeneous nutrient dosage throughout the irrigation cycle, which ensures a continuous and balanced feeding for the plants.

The reliability of this equipment is based on the Venturi injection system, made of resistant polymers and without moving parts, which minimizes maintenance and ensures long-lasting operation. In addition, they are highly compatible, allowing the injection of fertilizers and complementary products of different nature, thus offering greater flexibility.

Simplicity is another of its advantages, with easy and intuitive injection regulation that facilitates its use and allows quick and precise adjustments. Finally, the AZUD QGROW V model includes an advanced control with pH, electrical conductivity (EC) and temperature display, providing critical data for optimal injection adjustment and ensuring that nutrients are applied in the ideal conditions for absorption and effectiveness.

Automatic fertigation equipment

AZUD QGROW AT is the automatic fertigation equipment designed for simultaneous multi-injection of nutrients into the irrigation system. This equipment also works by means of a Venturi injection system made of polymers, with no moving parts, which guarantees reliability and low maintenance.

An advanced controller precisely manages irrigation and nutrition according to the needs of the crop, ensuring homogeneous dosing. This equipment allows the injection of various fertilizers and complementary products, offering compatibility and versatility.

In addition, they offer remote control to manage the system from anywhere, improving safety and efficiency. This design increases crop yield and quality, reduces input and labor costs, and minimizes environmental impact, contributing to a more sustainable agriculture.