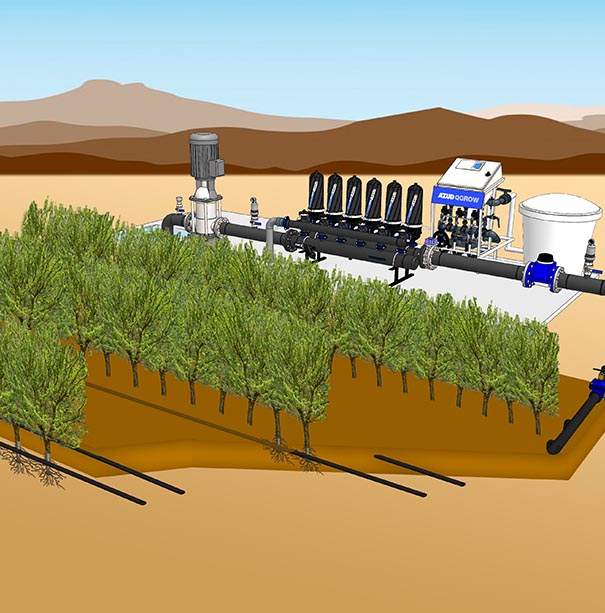

Subsurface drip irrigation systems (SDI) are an agronomic option suitable for all types of crops, either woody, such as almond, vine, olive, pistachio or peach trees, or extensive, such as maize, barley or alfalfa.

SDI is an irrigation technique that allows the localised supply of water and nutrients to the plant below the surface, optimising root and plant growth. This practice makes possible the use of water, energy and fertilisers, positioning it as the best alternative at an economic, agronomic and ecological level.

Increased irrigation efficiency.

Saving and improving fertigation.

Reduction of energy expenditure.

Possibility to use wastewater.

Reduction of crop water stress.

Reduced presence and development of weeds.

Reduces the risk of pests and diseases.

Positive evolution of the physical properties of the soil.

Reduction of animal damage and absence of vandalism.

It blends perfectly into the landscape.

No exposure to incident solar radiation.

Facilitates and reduces maintenance tasks.

Reduced maintenance costs.

Facilitates and reduces cultivation work.

SDI subsurface drip irrigation installations require specific design, installation, operation and maintenance criteria to take full advantage of the benefits of this system. The design criteria for determining the layout and sizing of the pipes are similar to those used in localised surface irrigation, but taking into account that we must consider a series of auxiliary elements in the installation to guarantee its proper handling, control and maintenance.

The additional auxiliary elements help us to verify that the installation is working properly, allow us to avoid and/or detect clogging problems in the emitters and ensure a longer service life of the installation. Some elements also help us to achieve a safer, more efficient and economical maintenance.

We have extensive experience in this drip irrigation solution, developing technology that accompanies the SDI, such as specific emitters with unique characteristics, ultra-efficient filtration and intelligent nutrition equipment, to guarantee the correct operation of the system over time.

We also have thousands of projects around the world in most crops, which allows us to provide the experience and knowledge of thousands of users in the application of this system.